GZ Multi Picking System

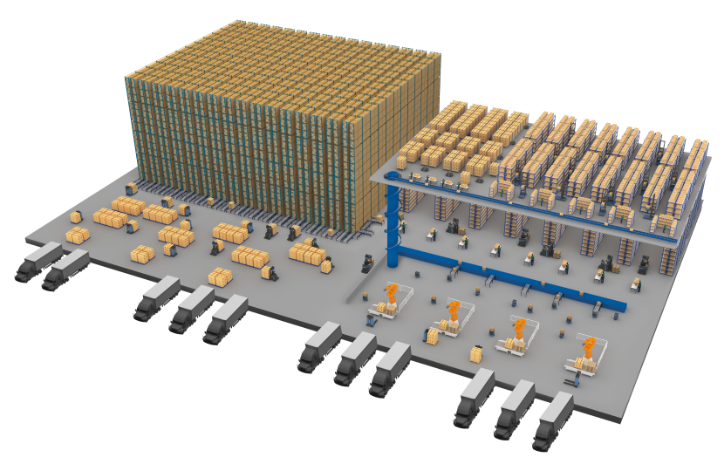

Warehouse robot solution for same-field storage and one-stop picking of small, medium and large pieces of goods, which significantly improves the utilization of longitudinal space for shelf picking, reduces the overall warehousing area, and improves the compatibility of storage, storage density and efficiency of storage in and out of the warehouse.

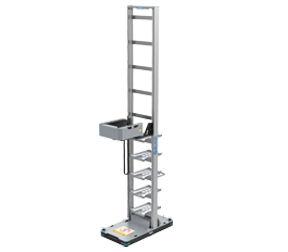

Related equipments: Picking, Ants, shelves, bins.

Application Scenarios: B2C and B2B large flow business in circulation area, medium and large anisotropic parts in industrial scenarios, whole box/unpacked picking and other business scenarios.

Flexibility

High business tolerance: respond to peaks and valleys by simply adjusting the work flow of different robots and increasing the number of robots.

Adaptation to multiple business forms: Widely applicable to B2C business in distribution industries such as e-commerce, retail, footwear and pharmaceuticals, as well as B2B store picking business in these industries.

Wide range of picking goods: the workstation can support picking of different sizes and weights, such as small, medium, large, shaped and heavy parts.

Compatibility

One-stop picking: one workstation can be compatible with whole-piece, whole-carton and split-piece picking to meet diversified storage and picking needs.

Innovative storage mode: The storage mode of “small on top and big on the bottom” realizes the storage of large and small pieces in the same space and is compatible with various sizes and weights of large pieces.

Multi-model mixing: breaking the boundaries of equipment and system, realizing unified scheduling of different models on the same map.

Expandability

Omni-directional space expandability: physical space expansion in all directions can be realized according to business development needs, increasing the library capacity.

AI system iteration: Based on the long-term operation of on-site business and data accumulation and analysis, the AI system can automatically generate strategy algorithms to improve operational efficiency.

Continuous process optimization: Simplify the picking process without the need for combined order or relay picking, one-stop completion of diversified order picking, and improve the overall operational efficiency.

Digital Intelligence

Large-scale scheduling: Supports simultaneous mixed scheduling of more than 1,000 robots of multiple types, dynamic planning, deadlock prevention, and congestion elimination.

Data Intelligent Algorithm: Multiple intelligent picking algorithms to meet diverse needs and maximize robot utilization.

Data-driven decision-making: timely capture and automatic warning of system anomalies to avoid potential production interruptions, multi-dimensional data analysis and visualization to assist business decision-making and operation optimization.