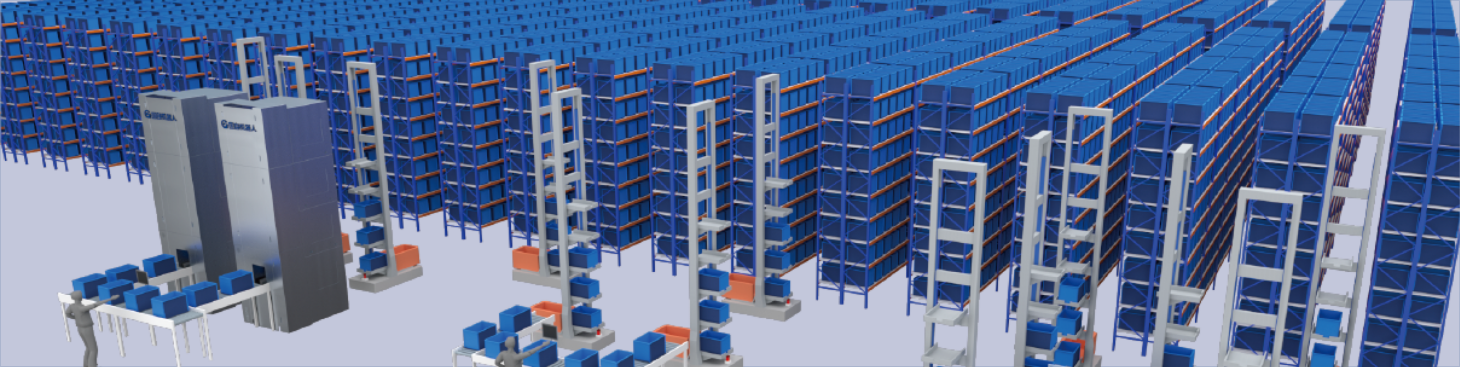

A highly efficient, high-density goods-to-person intelligent picking system designed to meet diverse needs, including carton box mixing and multiple box specifications.

A warehouse robot solution for same-field storage and one-stop picking of small, medium, and large items. This system significantly improves the utilization of vertical space for shelf picking, reduces the overall warehousing area, and enhances compatibility, storage density, and the efficiency of inbound and outbound warehouse operations.

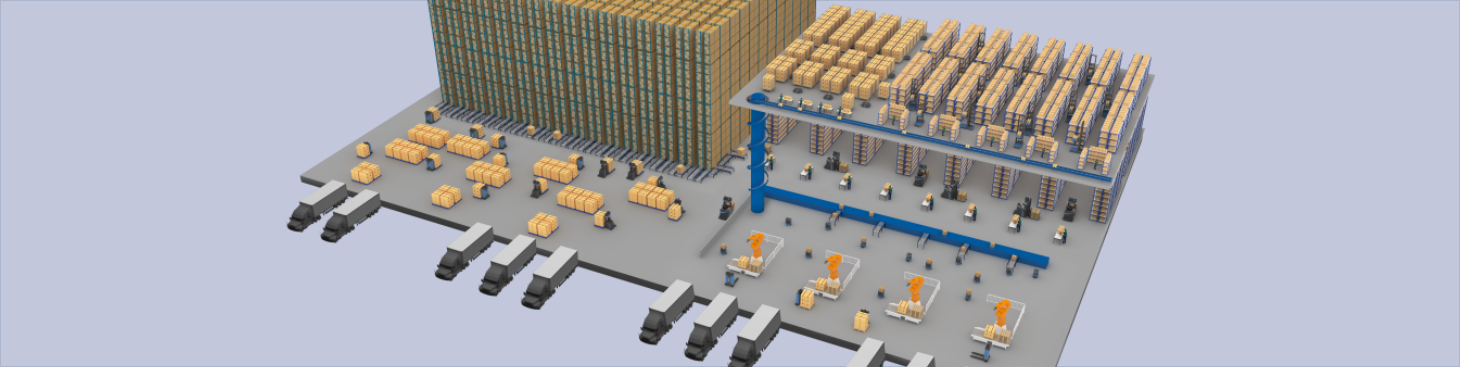

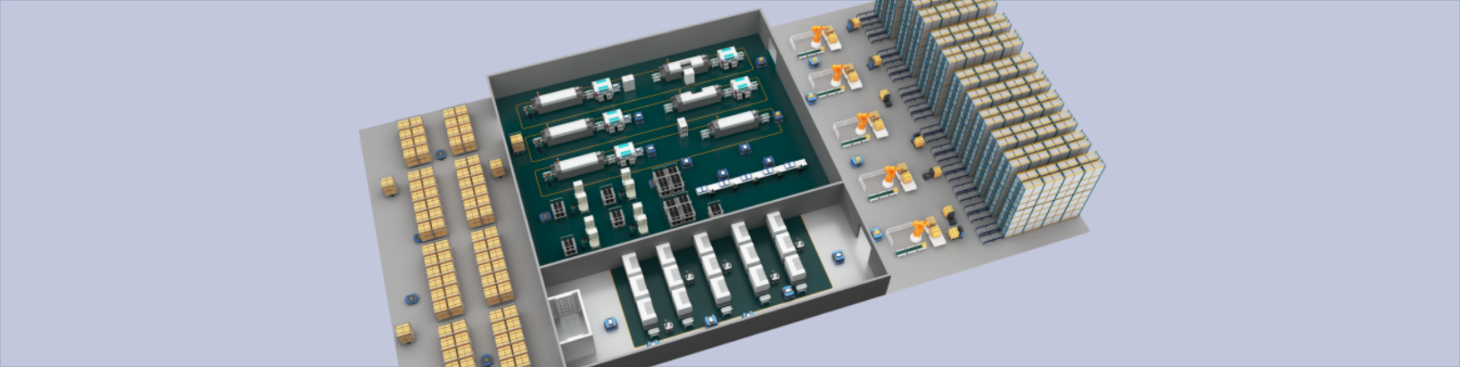

Centered around the core concept of 'goods to people, orders to people,' this integrated warehousing and logistics solution includes three major product systems: mobile robots (ANTS AGV), a robot dispatch management system (RCS), and an intelligent warehouse management system (iWMS). This solution revolutionizes traditional warehousing and logistics operations, significantly enhancing warehousing efficiency.

The integrated solution for industrial logistics is based on flexible handling robot ANTS and robot dispatching management system (RCS) as the core, breaking the logistics handling bottleneck of discrete process in factories, redefining intelligent handling, improving production line productivity and significantly reducing labor costs.